CNC Machining

Subtractive Manufacturing is a process by which 3D objects are constructed by successively cutting material away from a solid block of material.

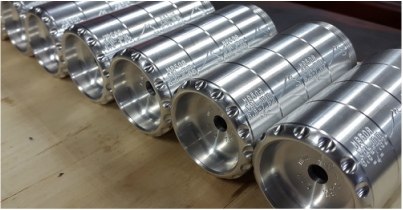

There is no substitute for CNC machining when it comes to producing large volumes of parts out of metals, plastics or wood. An added benefit of CNC Machining is that it allows for reduced piece part prices when ordering higher part quantities.

Sophisticated multi-tasking CNC machines are capable of producing high precision, functional prototypes and end products from real engineering grade plastics and metals to accurate tolerances.

Subtractive Manufacturing is a process by which 3D objects are constructed by successively cutting material away from a solid block of material.

There is no substitute for CNC machining when it comes to producing large volumes of parts out of metals, plastics or wood. An added benefit of CNC Machining is that it allows for reduced piece part prices when ordering higher part quantities.

Sophisticated multi-tasking CNC machines are capable of producing high precision, functional prototypes and end products from real engineering grade plastics and metals to accurate tolerances.

|

CNC Machining Applications:

CNC Machine facilities:

|

The use of 4th axis rotary tables and innovative machining fixtures allows us to minimize setup and switch over times thus ensuring an accurate and repeatable machining process.

Any machined parts can therefore be analysed for improved material selection, part functionality and cosmetic appearance early in the prototype development process.

CNC Machining plastic prototypes is much quicker and more cost effective than the alternative method of Molding prototypes as no mold tooling is required up front.

The CNC machining process is either driven by the customers' supplied 3D CAD Model, or alternatively, from the Red Dog designed and developed product 3D CAD model..

CNC Programming on CAM software allows us to establish best possible machining processes and problem areas before actually setting up to cut any material..

Any CNC machined plastic parts are delivered as-milled, leaving visible cutter / tool marks. Metal parts however, can be polished as required.

Red Dog CNC offers a turnkey prototyping solution which includes sourcing of exotic materials, accessories and special finishes.

Any machined parts can therefore be analysed for improved material selection, part functionality and cosmetic appearance early in the prototype development process.

CNC Machining plastic prototypes is much quicker and more cost effective than the alternative method of Molding prototypes as no mold tooling is required up front.

The CNC machining process is either driven by the customers' supplied 3D CAD Model, or alternatively, from the Red Dog designed and developed product 3D CAD model..

CNC Programming on CAM software allows us to establish best possible machining processes and problem areas before actually setting up to cut any material..

Any CNC machined plastic parts are delivered as-milled, leaving visible cutter / tool marks. Metal parts however, can be polished as required.

Red Dog CNC offers a turnkey prototyping solution which includes sourcing of exotic materials, accessories and special finishes.

© 2021 Red Dog CNC. - All rights reserved worldwide.